Schematic Drawings Screen Printing

I created the following drawings to explain screen printing to my students. They are shown in my lecture on screen printing technology. I hereby make the drawings available to you for your own use, but it would be very nice if you could mention my website as source. Originally the graphics were drawn with the Microsoft Office tools, then saved as *.emf and *.jpg files and converted to *.svg vector graphics with inkscape.

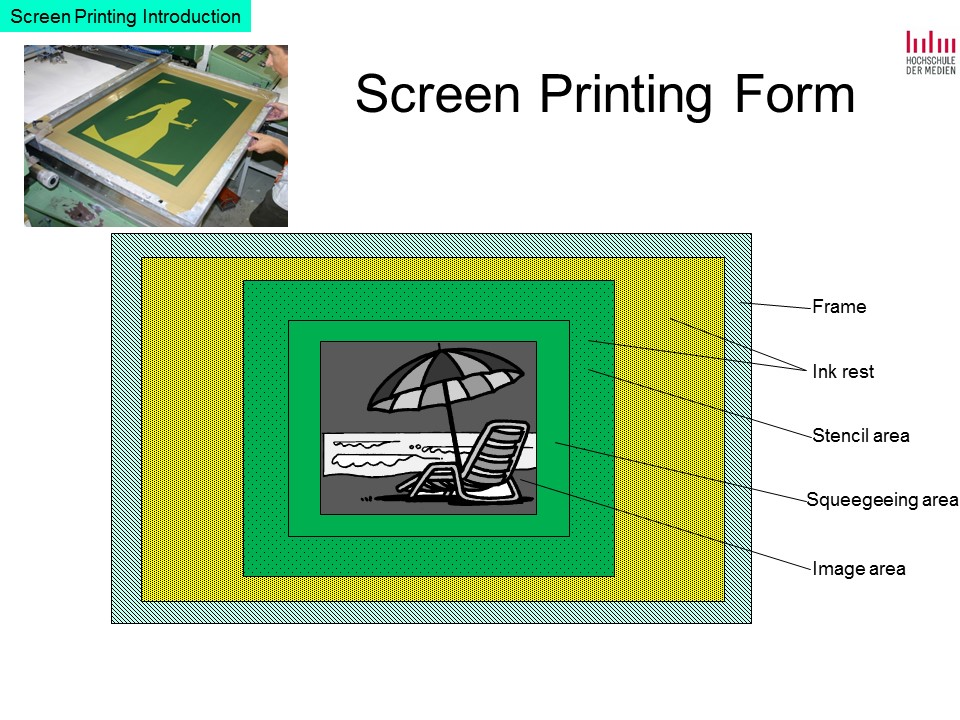

1. Screen Printing Form:

Screen Printing Form with Designations:

|

Screen_Printing_Form.EMF Screen_Printing_Form.svg |

2. Four Variants of Screen Printing:

Flat Bed Screen Printing

|

|

FlatbedSP.EMF FlatbedSP.svg |

As the name suggests, with this printing principle, the screen printing form is flat and the substrate lies flat under it as a flexible or rigid structure. There is a small gap between the printing plate and the substrate, which is called "snap off distance". During printing, the squeegee is pressed down and comes into line contact with the substrate. Due to the adhesive strength of the printing ink, the substrate must usually be held on the printing table with a vacuum or with a removable adhesive. Printing can be carried out with manual printing tables of various designs or with flatbed screen printing machines with different levels of mechanization up to a fully automatic screen printing line. The simple construction of this variant allows for the largest print formats up to 4x11m.

Flatbed Cylinder Screen Printing

|

|

FlatbedCylinderSP.EMF FlatbedCylinderSP.svg |

With this printing principle the screen printing form is flat, similar to flatbed screen printing. The flexible, mostly sheet-like printing material is fed via a feeder to the gripper system of the impression cylinder, which is located under the printing form. The printing form and the impression cylinder move synchronously. The printing squeegee, which is fixed above the apex of the impression cylinder, conveys the screen printing ink onto the substrate as it moves forward. As the screen printing form returns, the squeegee lifts off and the floodbar distributes the ink evenly over the screen printing forme. The flatbed cylinder screen printing presses are usually designed as fully automatic machines with an automatic sheet feeder and automatic transport into a drying system.

Rotational Screen Printing

|

|

RotationalSP.EMF RotationalSP.svg |

In rotary screen printing, the substrate is flat and the printing form is designed as a sleeve or cylinder. The printing substrate, usually a textile, paper or plastic web, is moved under the cylindrical printing form. The cylinder rotates synchronously with the movement of the substrate. A fixed squeegee inside the cylinder transfers the printing ink, which is continuously pumped into the cylinder, onto the printing substrate. Rotary screen printing is used to print fabric webs (textiles), paper and plastic webs (wallpapers, labels), but also ceramic tiles (transported on special belts). Endless printing is possible. In label printing, rotary screen printing is often combined with other printing processes in so called hybrid presses.

Object or Screen Printing "in the Round"

|

|

ObjectSP.EMF ObjectSP.svg |

With this screen printing variant, the object to be printed itself becomes the counter impression body. It must have a so-called surface line which allows a rolling movement underneath the printing plate. Solid or hollow bodies, with cylindrical, round, conical or oval outer shape, usually made of glass, metal or plastic, are printed with a flat printing form or one that matches the contour of the printing material. The printing form moves under a fixed squeegee synchronously with the substrate in one direction. For printing on a spherical product, the printing plate is curved, following the cross-section of a hemisphere. The geometry of the squeegee corresponds to the curvature of the printing plate. Object screen printing can be carried out manually, with semi-automatic or fully automatic multicolour machines.