Student's Project Work Including LED-Lighting

Studentische Projektarbeiten, die LED-Beleuchtungen enthalten.

In the study program "Print and Media Technology" at the University of Media (Hochschule der Medien, HdM) Stuttgart one of the core items of the curriculum is a student project work that stretches over 2 semester. The goal of the work is to create and produce an extraordinary graphical, printed product, typically a book that features several printing processes or things like augmented reality etc. and comes in a kind of casket or something similar. Each year about 60 to 80 students work on such projects in groups of 8 to 12 persons. An HdM professor supervises the projects. During these projects the students start from the basic idea, go through an orientation and creative phase, develop the content and after finalizing the concept and the design phase they enter the production phase where they produce their product on the facilities the HdM offers, photo studio, Pre Press, plate making, printing presses, finishing equipment and packaging. Sometimes, if technologies are not available inside the HdM, then outside, well-befriended companies are involved.

In comparison to the Bachelor thesis, the “weight” of that project work is quite high since both, the thesis and the project work are honored with 12 ECTS.

Nice examples for such products are the calendar "Vita Studiosi" or a Web2Print cookbook, a nicely designed fairy tale book, or a book about the famous Live Jazz Club (The Bix) in Stuttgart with impressive photographs of the musicians in action. (More information provided by clicking on the links).

On this page two student’s projects are presented that included LED-Lightings, printed circuits and a battery embedded in a graphical product:

1. Project "mysterious items and riddles" (Projekt "Raetselhaftes") 2013/2014

2. Project "mouse seeking food" (Projekt "Maeusespiel") 2008 (at DRUPA)

1. Project Calendar "mysterious items and riddles" ("Raetselhaftes")

One of the recent examples of such a project work was a calendar for the VIP-customers of an insurance company Medienversicherung a.G. The title of that calendar was “Raetselhaftes” which means somewhat like mysteries and riddles. The participants and some more information is given in the documentation (in German) that is a booklet included in the jewel box.

Besides a lot of crossword puzzles and riddles concerning the printing technologies it contains some gimmicks like LED-Lighting, a pop-up, a model of an offset press where the cylinders can be revolved, a personalized route planner map to the location of the Medienversicherung a.G. and a mysterious bookmark magically turning a black and white drawing into color. 200 copies of the calendar were produced including the electronics and 300 copies without. The calendar itself is a pocket type calendar and is embedded in a casket or jewel box, which contains the pop-up with the LED-lighting and the battery.

Below you will find how the LED-lighting was realized and what kind of unexpected problems can occur.

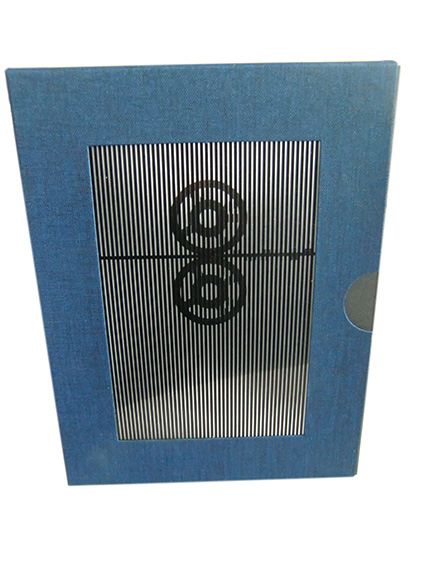

The gasket box contains a "moving image" as can be seen in this videoclip:

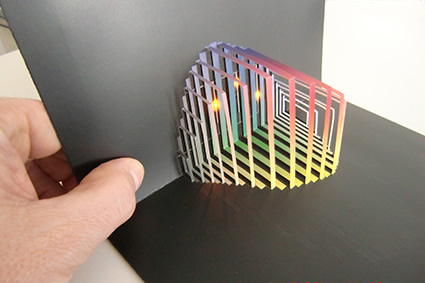

After opening the box you can unfold the pop-up with the LED-Lighting and push the "on"-button. Watch here:

On the right hand side of the box there is another gimmick. An assembly that depicts an offset press. Turn the wheels! Watch here:

Inside the calendar a mysterious bookmark can be found: Watch here how black and white turns into color:

Now, how does the circuitry work?

First of all to drive the LEDs a battery is needed. The company VARTA Microbattery GmbH sponsored the button cells CR2016 (20mm diameter) with attached soldering tags that drives the 3 LEDs.

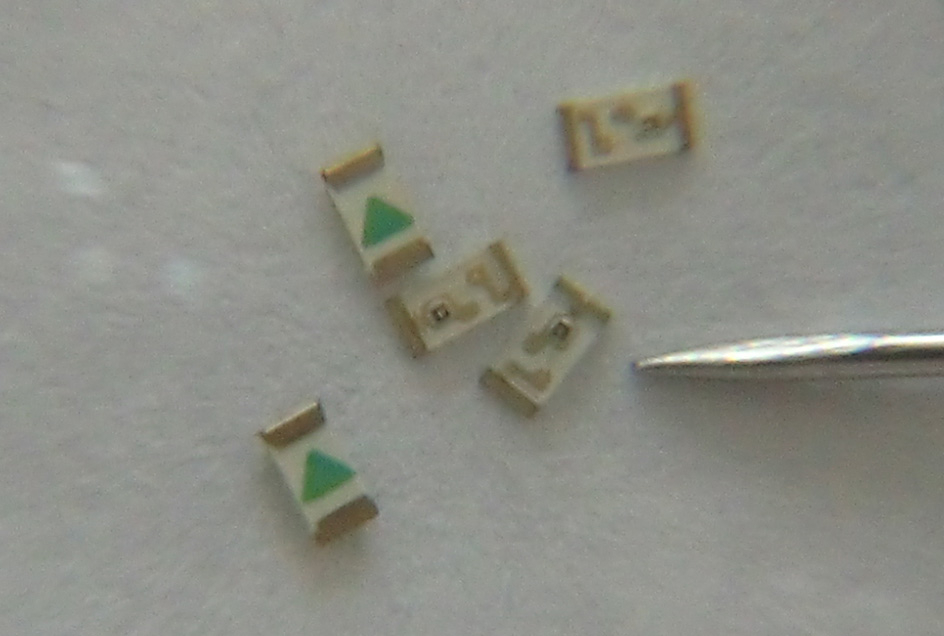

The LEDs (SMD type) were of type "super flat". The picture shows the SMD-LEDs in comparison with a pin. One LED purchased at an electronics discounter is about 0,11 EURO.

The circuit, comprising of conductive lines of silver ink, was printed onto a piece of about 10x15cm corrugated board.

The corrugated board is an E-flute with a thickness of 1.6mm. Into the corrugated board, a hole was punched with a diameter of 20mm in which the battery perfectly fits. The thickness of the button cell CR2016 is 1.6mm, thus, ideally match with the thickness of the corrugated board. The button cells had three soldering tags making it possible to bend one in S-Shape in order to attach to the contacts formed by a patch of the printed silver ink. The electrical contact was improved by a conductive silver lacquer that was applied manually by a small brush included in the small bottle. An electronic discounter offers such conductive silver lacquer (manufacturer FERRO) in bottles containing 3g for 11 Euro. Overall, six bottles were used.

The CR2016 battery (Lithium Manganese Dioxide) has a nominal Voltage of 3V. The LEDs, however, bear a maximum voltage of about 2.5V, only. In order not to destroy the LEDs there must be a series resistor. The resistor ideally should cause a voltage drop of about 0.5V. The typical current of a LED is 30mA. Thus, using Ohms law the resistor needs to be around 16 Ohms. The goal now was to print conductive lines that approximately match with the required resistance.

Assuming that the specific resistance of a printed silver paste is 2x10-5Ohmcm, then with a layer thickness of 15µm and a length of 20cm the printed line width should be around 100µm. First trial with screen-printing of 100µm lines onto the E-flute, however, failed because they showed quite a lot of interruptions especially in the valleys of the flutes. In spite the risk of applying too much voltage to the LED the line thickness was increased to about 250µm and then it worked. Fortunately without destroying the LEDs.

To assemble the LEDs onto the corrugated board pre-cut pick and place techniques were taken into account. It is difficult to find appropriate affordable methods especially for small volumes. One option was to rent a pick & place tool for a few days/weeks, another option was to use a p&p service from a be-friended university institute. The latter turned out to be only slightly cheaper. Finally, the students decided to assemble the LEDs themselves by hand. Students with good eyesight and steady hands did it manually (partly using head wearing lenses).

In the end, the calendar’s caskets were finalized and everything worked fine.

After two days after assembling then a shock: the LEDs did not work anymore. The batteries were empty! After reopening the assembly and examining the circuitry, the surprising reason could be found easily. The corrugated board that houses the batteries and the circuit is of black color (due to design reasons it should be black). The black surface of the corrugated board, however, turned out to be conductive! That means that the manufacturer of the corrugated board uses carbon black to produce the black surface. It is in the region of ~100kOhm and thus slowly discharged the batteries.

Could that be expected? All other black cardboard that was used is not conductive at all - as paper should. Since the assembly of more than 200 copies was a very laborious work, a simple and easy “repair solution” was required. How that was done and every copy fixed will be shown in the talk

In the “making of”-brochure included in the casket it is indicated that due to environmental reasons the batteries can be removed and the users are able to dispose them correctly.

Overall it was very much fun and we really learned a lot.

2. Project "Mouse Seeking Food"

This game was developed with a student group and manroland as the main sponsor already for DRUPA 2008.

In this figure the printed circuit inside the PET foil is shown. A flat battery (VARTA no longer produces this type) drives 3 LEDs. Each LED can be switched on by pressing the switches. The distance between the connecting pad and the fork-like contacts of the switch is provided by a corrugated board. All the graphics and drawings were done by Andreas Lorenz, a former student of the HdM, at that time working for manroland, Offenbach.

200 copies of the mouse game were produced.